Flame sensor issues cause approximately 80% of modern furnace lockouts, yet most homeowners have never heard of this component until their heat stops working. This tiny rod plays an outsized role in your home’s safety and comfort by detecting flame presence and preventing gas leaks. When carbon buildup or oxidation interferes with its operation, your furnace shuts down to protect you.

Understanding your flame sensor’s location, function, and maintenance requirements can prevent emergency breakdowns during cold weather. This guide covers everything from basic operation to troubleshooting common problems and knowing when to call The Chill Brothers.

TL;DR

Furnace flame sensors are safety tools for furnaces that detect flame presence and prevent gas leaks. They indicate whether or not the flame is burning in the furnace. Some issues like carbon buildup, oxidation, poor electrical connections, and sensor misalignments are commonly faced with the sensors. Regularly clean and check your sensors to make sure they are working perfectly.

What is a Furnace Flame Sensor?

Furnace flame sensors are typically slender metallic rods made of stainless steel. They are positioned in the path of the burner flame.

But why do furnaces need flame sensors?

The furnace flame sensor makes sure there is a burning flame inside the furnace when the valve is open. Otherwise, the gas that is supposed to burn will escape from the system. The unburned gas builds up in the furnace and/or the home. This may lead to:

- Gas leaks

- Potential carbon monoxide poisoning

- Waste of fuel

- Wear and tear due to short cycling (the incident where the furnace continuously turns on and off)

How Furnace Flame Sensors Work?

A furnace flame sensor’s primary function is to monitor the presence of a flame during the combustion process. The sensor works in conjunction with the furnace’s ignition system. It generates a spark or lights a pilot flame to ignite the main burner.

The flame sensor is connected to the furnace’s control board and the gas valve circuit. When the burner ignites, the flame sensor generates a small electrical current. This current is then sent back to the control board, signaling that a flame is present. If the sensor fails to detect a flame, the control board will shut off the gas supply to prevent the release of unburned gas into the environment, ensuring safety.

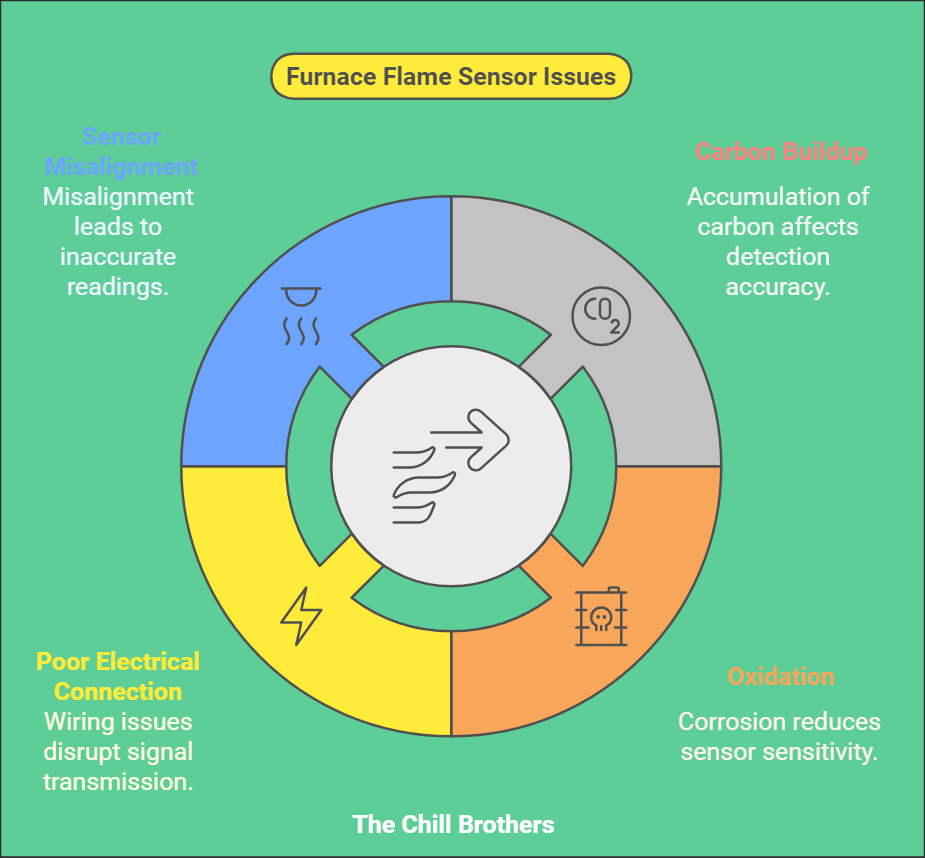

Common Issues of Furnace Flame Sensors

Like any other component in an HVAC system, furnace flame sensors can experience issues over time. Some common problems include:

Carbon Buildup

Carbon and debris from the combustion process accumulate on the sensor over time. It affects the sensor’s ability to detect the flame accurately.

Oxidation

The metal surface of the sensor may corrode due to exposure to combustion byproducts and moisture. It results in decreased sensitivity.

Poor Electrical Connection

Wiring issues or a loose connection between the flame sensor and the control board can disrupt the signal transmission.

Sensor Misalignment

Improper positioning of the sensor with the burner flame can hinder its ability to detect the flame.

It’s crucial to address these issues promptly to ensure the reliable operation of your furnace.

Some of the signs that your flame sensor may need repair include:

- Frequent burner cycling

- Difficulty in maintaining a consistent flame

- The furnace shut off unexpectedly.

If you are experiencing any of these furnace flame sensor issues, it is always recommended to reach out to experts like The Chill Brothers. If you need expert HVAC repair, check their services in Houston here.

Basic Maintenance Tips of Flame Sensors

To keep your furnace flame sensor in optimal condition, consider the following maintenance tips:

Regular Cleaning

Periodically clean the flame sensor using a fine emery cloth or steel wool to remove accumulated carbon and debris. Ensure the furnace is turned off before attempting any cleaning.

Visual Inspection

Check for signs of oxidation or corrosion on the sensor. If you notice any, gently clean the affected areas and consider applying a thin layer of high-temperature anti-oxidation paste.

Secure Electrical Connections

Inspect the wiring connecting the flame sensor to the control board for any signs of wear or damage. Tighten any loose connections and replace damaged wiring.

To further prevent your furnace from issues, it is beneficial to enroll in the Chill Preventive Maintenance Plan! With this plan, you can receive thorough, bi-annual tune-ups to ensure your system is prepared for anything! Give The Chill Brothers a call today or visit their website for more information.

Conclusion

Furnace flame sensors are unsung heroes in the world of HVAC, quietly ensuring the safety and efficiency of our heating systems. Understanding their operation, recognizing common issues, and performing regular maintenance can go a long way in preventing disruptions and costly repairs. If you encounter persistent problems or are unsure about the condition of your furnace flame sensor, it’s advisable to consult with a professional HVAC technician to ensure the continued comfort and safety of your home.

I’m Francis Kaspar, a 35-year-old HVAC technician with over 10 years of experience in the industry. I hold a certification in HVAC technology from Texas State Technical College, where I gained hands-on skills that shaped my career.

Currently, I’m working at The Chill Brothers, specializing in AC installation, repair, and energy-efficient solutions. Outside of work, I enjoy spending time with my wife and two kids.

I’m also passionate about sharing my HVAC knowledge written by articles that provide practical tips and tricks for homeowners.